Turbulence boundary conditions

From CFD-Wiki

| Line 36: | Line 36: | ||

:<math>\delta</math> is the boundary layer thickness, which in fully developed pipe flow is the radius, or half the [[hydraulic diameter]], <math>d_h</math>. | :<math>\delta</math> is the boundary layer thickness, which in fully developed pipe flow is the radius, or half the [[hydraulic diameter]], <math>d_h</math>. | ||

| - | :<math>f</math> is the Darcy-Weisbach friction factor. | + | :<math>f</math> is the [https://en.wikipedia.org/wiki/Darcy%E2%80%93Weisbach_equation Darcy-Weisbach friction factor]. |

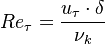

:<math>Re_\tau = \frac{u_\tau \cdot \delta}{\nu_k}</math> is the Reynolds number based on the friction velocity <math>u_\tau</math> and the kinematic viscosity <math>\nu_k</math>. | :<math>Re_\tau = \frac{u_\tau \cdot \delta}{\nu_k}</math> is the Reynolds number based on the friction velocity <math>u_\tau</math> and the kinematic viscosity <math>\nu_k</math>. | ||

Revision as of 23:48, 7 December 2024

This section is under construction, please do not trust the information available here yet

Introduction

Fully developed turbulent pipe-flow inlet

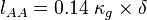

For fully developed turbulent pipe flow the turbulence inlet properties can be estimated using the model presented by Basse in Table 1 of [1].

The subscript  here denotes an area-averaged value. The model parameters

here denotes an area-averaged value. The model parameters  ,

,  ,

,  and

and  can be computed using the following general function:

can be computed using the following general function:

Where the a, b, c and d constants have been fitted using Princeton Superpipe measurements [2] as described in [3] and [4]:

| Parameter | a | b | c | d |

|---|---|---|---|---|

| −1.18 | 1.52 | 2.15e-4 | -8786 |

| 2.21 | -0.60 | 3.97e-5 | 11186 |

| 1.28 | -0.32 | 5.85e-5 | 4609 |

| 1.03 | -0.91 | 3.30e-5 | -11755 |

is the boundary layer thickness, which in fully developed pipe flow is the radius, or half the hydraulic diameter,

is the boundary layer thickness, which in fully developed pipe flow is the radius, or half the hydraulic diameter,  .

.

is the Darcy-Weisbach friction factor.

is the Darcy-Weisbach friction factor.

is the Reynolds number based on the friction velocity

is the Reynolds number based on the friction velocity  and the kinematic viscosity

and the kinematic viscosity  .

.

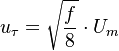

The friction velocity  can be computed using the friction factor

can be computed using the friction factor  and the mean pipe flow velocity

and the mean pipe flow velocity  using the formula:

using the formula:

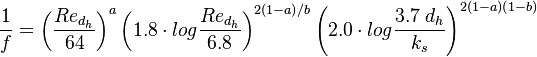

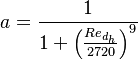

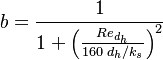

A good estimate for the friction factor  in pipe flow is Cheng's correlation [13]:

in pipe flow is Cheng's correlation [13]:

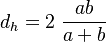

The hydraulic diameter  is the diameter of a circular pipe. For a rectangular pipe with width

is the diameter of a circular pipe. For a rectangular pipe with width  and height

and height  the hydraulic diameter can be computed from

the hydraulic diameter can be computed from  .

.

The equivalent sand-grain-roughness  is dependent on the pipe surface properties.

is dependent on the pipe surface properties.

Information below is old and will be reformulated

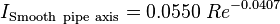

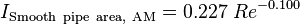

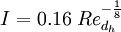

For fully developed duct flow the turbulence intensity at the core can be estimated as [1]:

,

,

where  is the Reynolds number based on the pipe hydraulic diameter

is the Reynolds number based on the pipe hydraulic diameter  . Additional details on the derivation can be found in [2].

. Additional details on the derivation can be found in [2].

Russo and Basse published a paper [3] where they derive turbulence intensity scaling laws based on CFD simulations and Princeton Superpipe measurements. The turbulence intensity over the pipe area is defined as an arithmetic mean (AM). The measurement-based scaling laws are:

Scaling using other turbulence intensity definitions is investigated in [4,5]. Here, it is also found that turbulence intensity scales with the friction factor, both for smooth- and rough-wall pipe flow. Code for an example in [5] can be found in [6]. A high Reynolds number transition in the scaling has been characterized in [7,8]. Turbulence intensity scaling extrapolated to extreme Reynolds numbers is studied in [9].

References

[1] Basse, N.T. (2023), "An Algebraic Non-Equilibrium Turbulence Model of the High Reynolds Number Transition Region", Water 2023, 15, 3234. https://doi.org/10.3390/w15183234.

[2] Hultmark M, Vallikivi M, Bailey SCC and Smits AJ. (2013), "Logarithmic scaling of turbulence in smooth- and rough-wall pipe flow", J. Fluid Mech. 728, 376-395.

[3] Basse, N.T. (2023), "Supplementary Information: An algebraic non-equilibrium turbulence model of the high Reynolds number transition region", https://www.researchgate.net/publication/373108195_Supplementary_Information_An_algebraic_non-equilibrium_turbulence_model_of_the_high_Reynolds_number_transition_region.

[4] Basse, N.T. (2021), "Scaling of global properties of fluctuating streamwise velocities in pipe flow: Impact of the viscous term", Physics of Fluids, vol. 33, 125109, https://arxiv.org/abs/2109.11626.

[13] Cheng, N-S (2009), "Formulas for Friction Factor in Transitional Regimes", Journal of Hydraulic Engineering 134 (9): 1357–1362. doi:10.1061/(asce)0733-9429(2008)134:9(1357). hdl:10220/7647. ISSN 0733-9429, https://dr.ntu.edu.sg/bitstream/10356/93959/2/Formulas_for_friction_factor_in_transitional_regimes%5B1%5D.pdf.

[1] ANSYS, Inc. (2022), "ANSYS Fluent User's Guide, Release R1", Equation (7.71).

[2] Basse, N.T. (2022), "Mind the Gap: Boundary Conditions for Turbulence Modelling", https://www.researchgate.net/publication/359218404_Mind_the_Gap_Boundary_Conditions_for_Turbulence_Modelling.

[3] Russo, F. and Basse, N.T. (2016), "Scaling of turbulence intensity for low-speed flow in smooth pipes", Flow Meas. Instrum., vol. 52, pp. 101–114.

[4] Basse, N.T. (2017), "Turbulence intensity and the friction factor for smooth- and rough-wall pipe flow", Fluids, vol. 2, 30.

[5] Basse, N.T. (2019), "Turbulence intensity scaling: A fugue", Fluids, vol. 4, 180.

[6] Basse, N.T. (2019), "Python code to calculate turbulence intensity based on Reynolds number and surface roughness.", https://www.researchgate.net/publication/336374461_Python_code_to_calculate_turbulence_intensity_based_on_Reynolds_number_and_surface_roughness.

[7] Basse, N.T. (2021), "Scaling of global properties of fluctuating and mean streamwise velocities in pipe flow: Characterization of a high Reynolds number transition region", Physics of Fluids, vol. 33, 065127.

[9] Basse, N.T. (2022), "Extrapolation of turbulence intensity scaling to Re_tau >> 10^5", Physics of Fluids, vol. 34, 075128, https://arxiv.org/pdf/2208.11479.

![I_{AA} = \sqrt{\left[ B_g + \frac{3}{2} A_g - \frac{8 C_g}{\sqrt[3]{Re_\tau}}\right] \times \frac{f}{8}}](/W/images/math/4/a/9/4a9bc23662ddc372ef070d824b7e75e8.png)

![Q(Re_\tau) = a + b \cdot tanh(c \cdot [Re_\tau - d])](/W/images/math/b/0/7/b07b24c846c7110e6d98deff6ce2ad88.png)